By Randy D. Robbins

Synopsis by JP Russell: The article promotes the thought that nonconforming products and services escape your organization and reach the customer. Escaped products and services must be addressed so that they do not recur. Toward the end of the article, there is a handy chart showing the steps to address escapes. However, I also found the author’s review of the development of modern quality concepts was very good and well documented. A good introduction to problem-solving with a twist.

Note: JP Russell is Managing Director, Quality Web-Based Training. This article was submitted to QualityWBT via the “Become a Published Author” offer at the www.jprlearning.com website.

While there are many theories, methods, and tools for quality and continuous improvement, many companies fail to utilize the rather simple yet profoundly effective approach of what I call “Escapes Methodology”. Escapes Methodology is a systematic categorizing and analysis of any occasion where a customer is dissatisfied with an order (i.e. product defect, paperwork error, shipping error, complaint, etc.). The analysis is conducted to determine if and where the quality system failed, what actions can be taken to correct the issue, or what system modifications can be made to prevent a reoccurrence. This information is then communicated throughout the organization. Over time, the escapes decrease, quality improves, customer satisfaction increases, sales, and customer retention increases. The method does not replace the use of any quality tools or six sigma, but it uses these tools with fine precision applications that result in real improvements that add direct value to the customer. The details of implementing Escapes Methodology and some examples of its improvement effectiveness will be discussed later in this article.

Throughout this article, there are a few terms that may not be commonly used and I will define them here. First, an escape is a defect or error that reaches the customer. The term escape is used to group errors, such as product defects, paperwork errors, customer complaints, etc. together and elevate the level of urgency to the issue. To correct and eliminate escapes, they must first be verified through the collection of objective evidence. Objective evidence is proof, such as, actual returned defective product or documentation that substantiates the claim of the customer.

A wise man once said, “There’s nothing new under the sun”. While I generally agree with this statement, I have found that simply looking at things differently can provide new perspectives and opportunities. The foundation of Escapes Methodology has been around for many years; however, the use of Escapes Methodology seems to have been overlooked, perhaps because of its remarkable simplicity. Let us review some of the foundational elements of Escapes Methodology.

Product quality became a serious focus of companies around 1970 when they began to realize that foreign competition was making inroads into the once stable American markets. American companies began to analyze what the foreign competition was doing to win greater market share. With companies like Toyota, it was easy to see that the extreme reliability of their products was a direct result of their attitude toward quality. A superior product or service clearly outperformed those of inferior quality in all profitability areas. It became clearly apparent that the advantages quality provided were increased market share and profits (Pyzdek, 2000, pp. 1-2). As more American companies began to look at ways to instill quality into their products, many different standards were developed and embraced as the solution to the problem. The improvement in quality began to turn the tide; however, it did not take long for expectations to increase which called for greater advancement in the field of quality. Over time, quality has evolved through basically four distinct stages. These stages are inspection, statistical quality control, quality assurance, and finally strategic quality management (Pyzdek, 2000, p. 12). Each of these stages imparted a measure of improvement to quality and led to the next stage. Regardless of the name given to the stages of quality, one premise became elevated above all and encompassed the best of each stage. This premise is that regardless of the method, quality must be incorporated into the complete business system. This quality system then becomes a guide for business success. It should consider exactly what the customer requires, having well-defined processes for translating those requirements into internal actions, aligning tasks, and processes along common goals and objectives, key measures to manage by facts, continuous improvement, understanding and improving all critical processes, and satisfying the customer (George & Weimerskirch, 1994, pp. 1-5).

In looking at quality programs, it is easy to be carried away with fad-type, quick-fix programs, and bold slogans; however, a closer look at successful companies is necessary. In an article titled Roots Grow Good Things, Too, Mike Micklewright (2007) states, “…the root cause of Toyota’s success includes the development of a lean culture, constant focus on reduction of waste, respect, and involvement of all employees, and living in the spirit of W. Edward Deming’s 14 principles”. All the key elements of a systems approach to quality are embedded in these four points expressed by Micklewright and are essential to Escapes Methodology.

Another important recommendation for quality systems and the application of Escapes Methodology is to use a process approach. This involves applying the system of processes and combining and managing their interactions. At the core of any organization, there is a process or set of processes. These processes use resources and are managed to transform inputs into outputs. The methodology that is recommended for a process approach is known as PDCA, which stands for plan, do, check, act. The PDCA method is a continuous cycle that begins with the “plan” stage where objectives are established to deliver the required results. In the “do” stage the new process is implemented. This leads to the “check” stage where the process is monitored and measured. The results then lead to the “act” stage where corrective action is taken to improve the process performance. If the desired results are not obtained, the cycle continues back into the “plan” stage (Totoiu, 2005, p. 2). The value of the PDCA method becomes even more evident when considered for use as a guide for continuous improvement through Escapes Methodology.

When the strategy of improvement is applied to the systematic process of quality, the by-product is reduced waste and increased productivity. These by-products have a positive impact on cost and improve both profit margin and asset utilization. By taking continuous improvement a step further and applying other focused methods and approaches, many companies have reaped great rewards and have remained competitive in an ever-changing business environment (George & Weimerskirch, 1994, pp. 5-9).

A world-renowned expert on quality theory named Dr. W. Edward Deming was once quoted as saying (Clark, 1995, p. 1), “Willing workers doing their best won’t do it. You have to know what to do, then do your best.” Clark (1995, p. 1) goes on to say, “The right thing is determined by the customer who defines the requirements.” In analyzing the words of Deming and Clark, it is evident that their intensions are toward the aspect of continuous improvement. These simple statements describe some of the foundational aspects of Escapes Methodology.

Among the great contributions of Dr. Deming, one of the most well known is his fourteen points for management. These points are all worthy of mention and great consideration; however, the scope of this article does not allow for the full and adequate coverage. His point number five directly focuses on continuous improvement. The point is, identify problems and work continuously to improve the system. It goes on to further explain this point by stating that continuous improvement of the system requires seeking out methods for improvement. It also states that the search for quality improvement is never ending and results from studying the process itself; not the defects detected during inspection (Swift, Ross & Omachonu, 1998, p. 8). Escapes Methodology helps to identify problems, not just with products, but also with the quality system.

Juran’s contributions are also far reaching and cannot be addressed sufficiently in this article. One of the most significant teachings is his ten steps to quality improvement. These steps include building awareness of opportunities to improve, set goals for improvement, organize to reach goals, provide training, carry out projects to solve problems, and report progress.

He goes on to encourage companies to give recognition, communicate results, keep score, and maintain momentum by making annual improvement part of the regular systems and processes of the company (Swift, Ross & Omachonu, 1998, pp. 9-10). One technique that is incorporated into Escapes Methodology and has been found beneficial is called Lessons Learned. It is based on the thought that if actions remain the same they will produce the same results. Therefore, to achieve different results, lessons must be learned to promote and encourage different action or behavior. In the case of escapes, lessons learned can be communicated in a manner linking the past to the future to motivate the desired change. This is accomplished through a system of organized after-action meetings and data collection. Once the issues are communicated, the corrective action process can begin by considering what could have been done to prevent the occurrence of the error or defect. By systematically removing or reducing the opportunities for errors or defects, great improvements can be made (Morris & Jambor, 2003, 3-4).

While most companies either fail to recognize the benefit in addressing escapes or are apprehensive about facing the reality that escapes do occur, Escapes Methodology can be an essential element of continuous improvement and customer satisfaction. A statement that is common in quality is “what gets measured gets done”. As identified by Page (2006), enlightened measurements are needed for an organization desiring a broad and complete prospective of performance. The enlightened measurements include process-focused measurements of defect rates, scrap rates, and process capability and customer-focused measurements of complaints, returns, on-time delivery, and satisfaction. The measurement of escapes clearly falls within the area of customer focus and can be an indicator of process effectiveness.

When considering escapes, I thought about the advice offered by Dr. K. Ishikawa (1985), “…if products are improved in accordance with the complaints of consumers, the consumers will continue to buy. For that reason, information concerning complaints is very important (p. 82).” Ishikawa goes on to recommend that companies develop a system that encourages customers to file complaints and makes it easy for customers to return defective products. Once the defective products are returned, they can be analyzed to determine the root cause of the defect. By working together, the supplier and the customer create better quality products and become joint heirs to the benefits that occur from this interaction (Ishikawa & Lu, 1995, pp. 82-84).

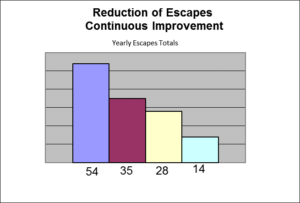

Now that I have described the foundational principles behind Escapes Methodology and provided a general understanding of what the method entails, I will now give an example of how successful it can be and briefly describe the steps for implementing the method (Table 1). Escapes Methodology has been remarkably successful and has had a profound impact on the few companies that have embraced it. Here are the results of one case study over a four-year period from initial inception (Figure 1).

Figure 1

As we are all aware, companies can be as diverse as any individual. The company represented above is a small, privately-held company. Along with its success in reducing escapes, it has also experienced improved sales, improved customer satisfaction, and improved profitability year after year since the initial inception of Escapes Methodology.

| Table 1 Escapes Methodology Steps | ||

| Step | Description | Key Considerations |

| 1 | Define escapes for your organization. | Returns, complaints, errors, what are customers calling you about? What occurrences cast a negative image of the organization? |

| 2 | Develop an escapes data collection method. | Ensure customer feedback is being collected. Assign a responsible party to collect the data. Most data are probably already being collected and just need to be located. |

| 3 | Collect escapes data for a benchmark and set a long-term objective for reduction or elimination of escapes. | You may collect data for a year or a fraction of a year to determine the current state of escapes. Identify escapes by area of origin or function. |

| 4 | Include reduction of escapes in your annual goals for continuous improvement and roll out the program to all employees. | Reduction of escapes can usually support an organization’s vision and mission statements and demonstrate their commitment to continuous improvement. If it doesn’t, revise the vision and mission statements. Demonstrating your commitment to continuous improvement is a requirement of most quality system standards. |

| 5 | Ask each area or function to make annual commitments to escapes reduction. | Based on escapes data collected, you can define the current state total for the organization and break down data for current state of each area or function. |

| 6 | When an escape occurs, verify each escape with the area or function. | This serves as a feedback mechanism to employees. Multiple errors may have caused the escape from multiple areas or functions. In that case, split the escape as appropriate. Ensure each area or function agrees to assume responsibility for the escape. |

| 7 | Focus on each escape as it occurs and apply laser focused corrective action to eliminate reoccurrence. | Apply quality tools as appropriate to the issue (e.g., 8D, 5 Why, six sigma, poka-yoke, SPC, etc.) The issue is elevated and communicated throughout the organization. |

| 8 | Report on escapes monthly. | Report to employees and break down for each area or function. This should be included for discussion in management review meetings. Elevating and communicating the issues again throughout the organization. |

| 9 | Evaluate progress annually and celebrate. | Report annually to the organization and include report in management review. Recognize areas or functions that have improved. Celebrate as a group for the entire organization to promote teamwork. |

| 10 | Go to step 4 until the long-term objective from step 3 is reached. | Observe the elements of Plan-Do-Check-Act. Report as continuous improvement. |

| In this brief overview of Escapes Methodology, I have attempted to spark your thinking about how this method might be beneficial to your organization. Companies often find they have not fully considered identifying and tracking escapes; let alone, incorporating Escapes Methodology into their quality system. From my experience, many good companies with good quality systems still have periodic escapes. Instead of just recovering from the escape and apologizing to your customer, make it important to everyone and use the occasion to bring real improvement to your quality system. References Clark, T.J. (1995 December). Doing the right thing right. Department of Defense Financial and Accounting Service Newsletter, pp. 10-13. George, S. & Weimerskirch, A. (1994). Total quality management: strategies and techniques proven at today’s most successful companies. New York, NY: John Wiley & Sons, Inc. Hopen, D. (2004, Spring). Consequences and changing behaviors. The Journal for Quality and Participation. Ishikawa, K. & Lu, D.J. (1985). What is total quality control? the Japanese way. Englewood Cliffs, NJ: Prentice Hall, Inc. Juran, J.M. & Gryna, F.M. (Eds.) (1988). Juran’s quality control handbook (4th ed.). New York, NY: McGraw-Hill. Micklewright, M. (2007, March 27). Roots grow good things, too. Quality Digest’s Quality Insider. Morris, M.A., & Jambor, D.F. (2003, September 9-10). Achieving flawless launches. Paper presented at the Robotic Welding conference of the Society of Manufacturing Engineers, Cleveland. Page, T. (2006). A justification for relevance in performance measurement criteria. Technical publication # TP06PUB152, Society of Manufacturing Engineers, Dearborn, MI. Pyzdek, T. (2000). Quality engineering handbook. Tucson, AZ: Quality Publishing, LLC. Swift, J.A., Ross, J.E., & Omachonu, V.K. (1998). Principles of total quality. (2nd Ed.). Boca Raton, FL: St. Lucie Press. Totoiu, D. (2005). Implementation of effective quality management systems in small companies. Paper presented at the WESTEC conference of the Society of Manufacturing Engineers, Los Angeles. © 2017 QualityWBT Center for Education/J.P. Russell & Associates 888.737.4488 (toll free)

|